3D Printers

Taking Higher Education to the Next Level

3D Printing Solutions for Education & Research

College and universities with 3D printing technology can prepare students for a workforce that demands sharp critical thinking and collaboration skills. The right technology attracts not only bright students but also talented faculty and valuable industry partners, leading to valuable business partnerships that can give undergrads vital real-world experience.

Stratasys

Bringing 3D printing into the classroom or lab exposes learners to the same cutting-edge technologies they’ll encounter in their careers. Tech-Labs is proud to offer FDM, PolyJet, and Stereolithography 3D printing solutions from Stratasys.

Renishaw

Renishaw's metal powder bed fusion is an advanced additive manufacturing process that allows you to make complex metal parts direct from 3D CAD data in a variety of metals, including titanium alloy Ti6Al4V, cobalt-chromium, stainless steel, nickel alloys Inconel 625, and Inconel 718 and aluminum alloy AlSi10Mg.

Solutions Center

To learn how 3D technology empowers schools, universities and laboratories, or to try cutting-edge learning tools hands-on, schedule a visit to our Solutions Center or request a sample part today!

-

Item Number:F170 / F370The Stratasys F Series is the ultimate, all-in-one rapid prototyping system for your entire team. It combines the power of FDM with the ease of GrabCAD Print for the most versatile and intelligent solution available.

-

Item Number:J55The Stratasys J55 Prime 3D printer introduces full color, high fidelity with tactile, functional, and sensory capabilities - making the efficiency and quality of PolyJet Technology more affordable and office-friendly than ever.

-

Item Number:J850 DAPThe Stratasys J850™ Digital Anatomy™ 3D Printer combines materials and software to create 3D medical models of human anatomy that mimic bone and tissue with realism you can see and feel.

-

The Digital Anatomy Creator (DAC) is a powerful tool that creates unique presets, prepares models for printing, and enables sharing projects.

-

Item Number:F190CR and F370CRIt starts with high-strength composite materials, but the Stratasys composite-ready F Series offers much more. More materials, more reliability – more capability than other similar printers.

-

Freemelt ONE is designed to make materials not yet known to mankind. Materials that engineers dream about. Materials that give us lighter, stronger and more efficient products.

-

HERON AM is Caracol's Large-Format Additive Manufacturing system: a robotized extrusion head, with direct and continuous feeding of composites and polymers, a dedicated software platform for the most complex tool paths, and many more features to fully integrate all that is needed to manufacture advanced industrial parts.

-

The Stratasys J35™ Pro is an affordable, versatile PolyJet 3D printer suitable for shared spaces offering multi-material capabilities.

-

The Stratasys MediJet™ is setting a new standard for medical printing. With multiple materials and multicolor capabilities, you can create brilliantly vivid anatomical models and drilling and cutting guides* that are sterilizable and biocompatible - all on a certified system.

-

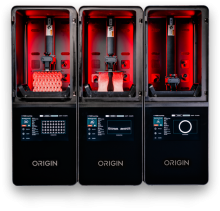

A transformative 3D printer enabling mass production of end-use parts in a diverse range of high-performance materials. Achieve industry-leading accuracy, consistency, detail and throughput with the P3™ Programmable Photopolymerization technology.