Electro-Mechanical Maintenance

Bayport Technical’s Heat Transfer training products teach key skills related to the installation, operation, and maintenance of heat transfer components and systems. Products found within Bayport Technical's Heat Transfer category cover applications commonly found in chemical plants, HVAC applications, power stations, petrochemical plants, petroleum refineries, and more! The available Heat Transfer training tools are an integral part of many major industries, including chemical manufacturing, oil and gas, and power generation.

Training Systems

Bayport's electro-mechanical maintenance training systems offer a variety of hands-on training solutions. Whether you need to teach basic electro-mechanical maintenance skills, shaft alignment, complete pump maintenance, gear, belt, and chain drive, or hands-on lock-out/tag-out practice, we have what you need.

150-FGT | Flange and Gasket Training System

Bayport Technical's Flange and Gasket Trainer (150-FGT) is designed to incorporate air and water pressure with numerous industry typical blind flanges, gaskets, flanged ports and valves to simulate field conditions in a variety of exercises involving craft, maintenance and safety skills with gasket selection, change procedures, torque performance, blind placement and a variety of additional training opportunities.

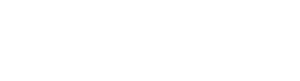

150-LOTO2B | Lockout Tagout Training System

This system provides hands-on safety training for a wide variety of common process activities, both mechanical and electrical. The unit is capable of demonstrating the necessary procedures of locking out different valves or parts of the equipment in order to isolate individual sections. The unit can also demonstrate electrical processes involving the isolation of switch boxes via breaker boxes and switches.

150-LOTOC | Lockout Tagout Training System

Bayport Technical's Lockout Tagout Training System, Single & Double Block & Bleed (150-LOTOC) is a set of SS LOTO tables with one single block and bleed and one double block and bleed.

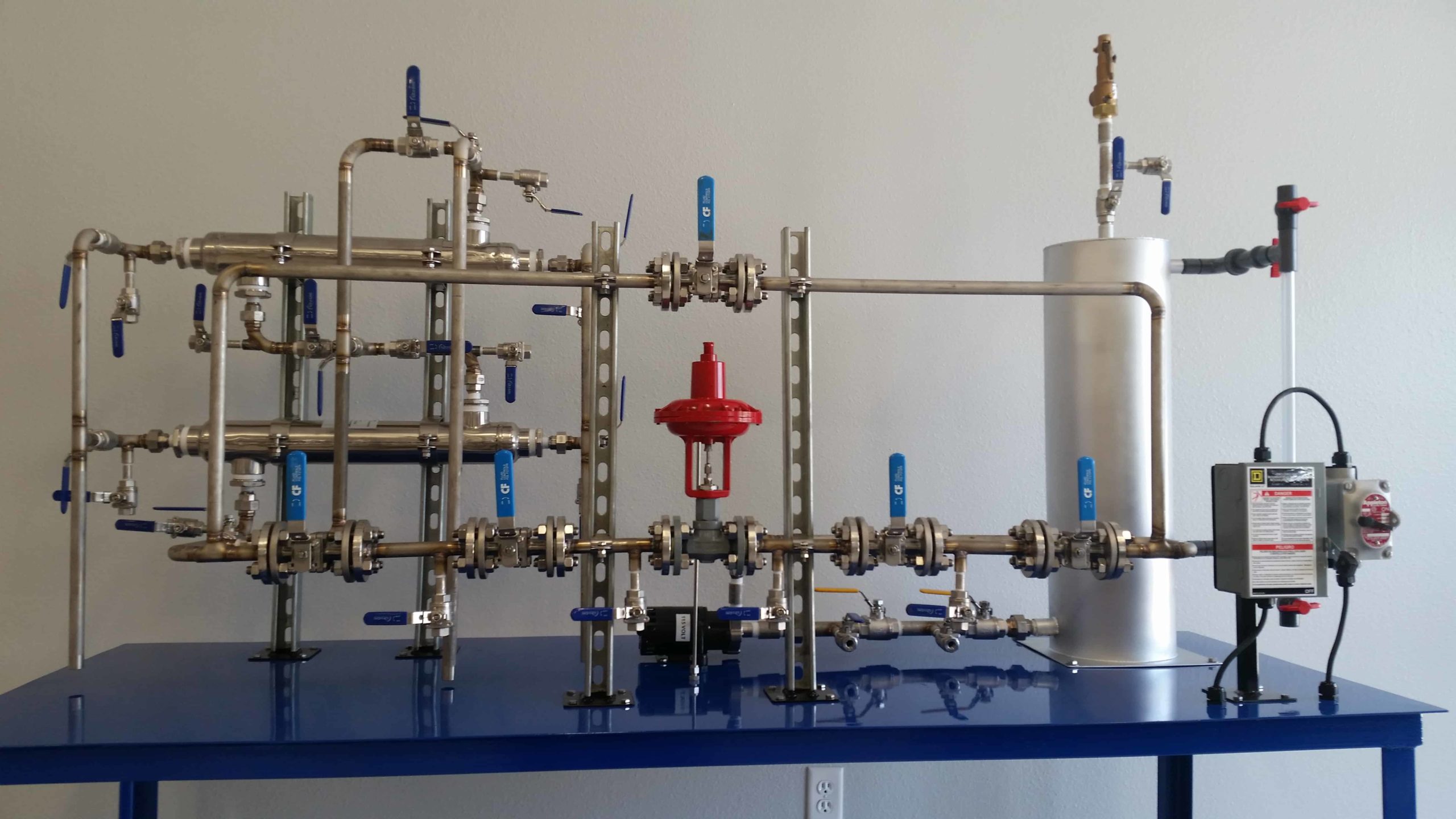

150-MT | Maintenance Training System

Bayport Technical's Maintenance Training System was designed to provide hands-on training for a wide variety of common process activities. Training exercises with this unit include alignment and coupling exposure, complete pump maintenance, electric motor and associated control systems, including lock-out tag-out exercises.

150-SMMT | Standard Multiple Mechanical Training System

Designed to provide maintenance and operations personnel with hands-on exposure to a variety of common mechanical situations inherent to industrial processes to progress through the full range of skills using one comprehensive unit. This unit can develop skill sets on vertical and various horizontal shaft alignment, gear drives, belt drives, chain drives, pump maintenance, and lock-out/tag-out.

Working Demonstrators

Bayport's electro-mechanical maintenance working demonstrators offer learners realistic, first-hand visualization into the inner-workings of industrial components and structures.

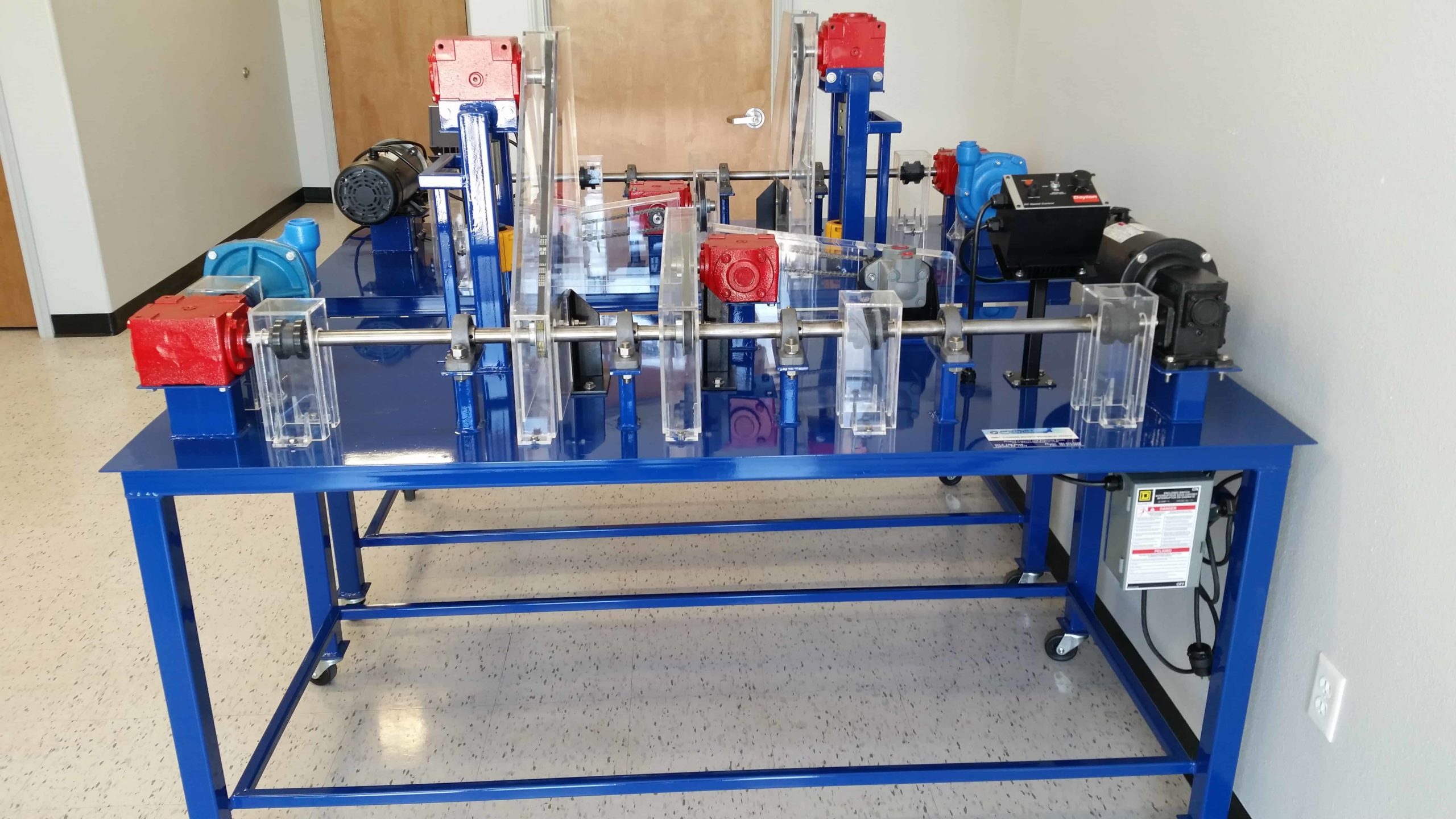

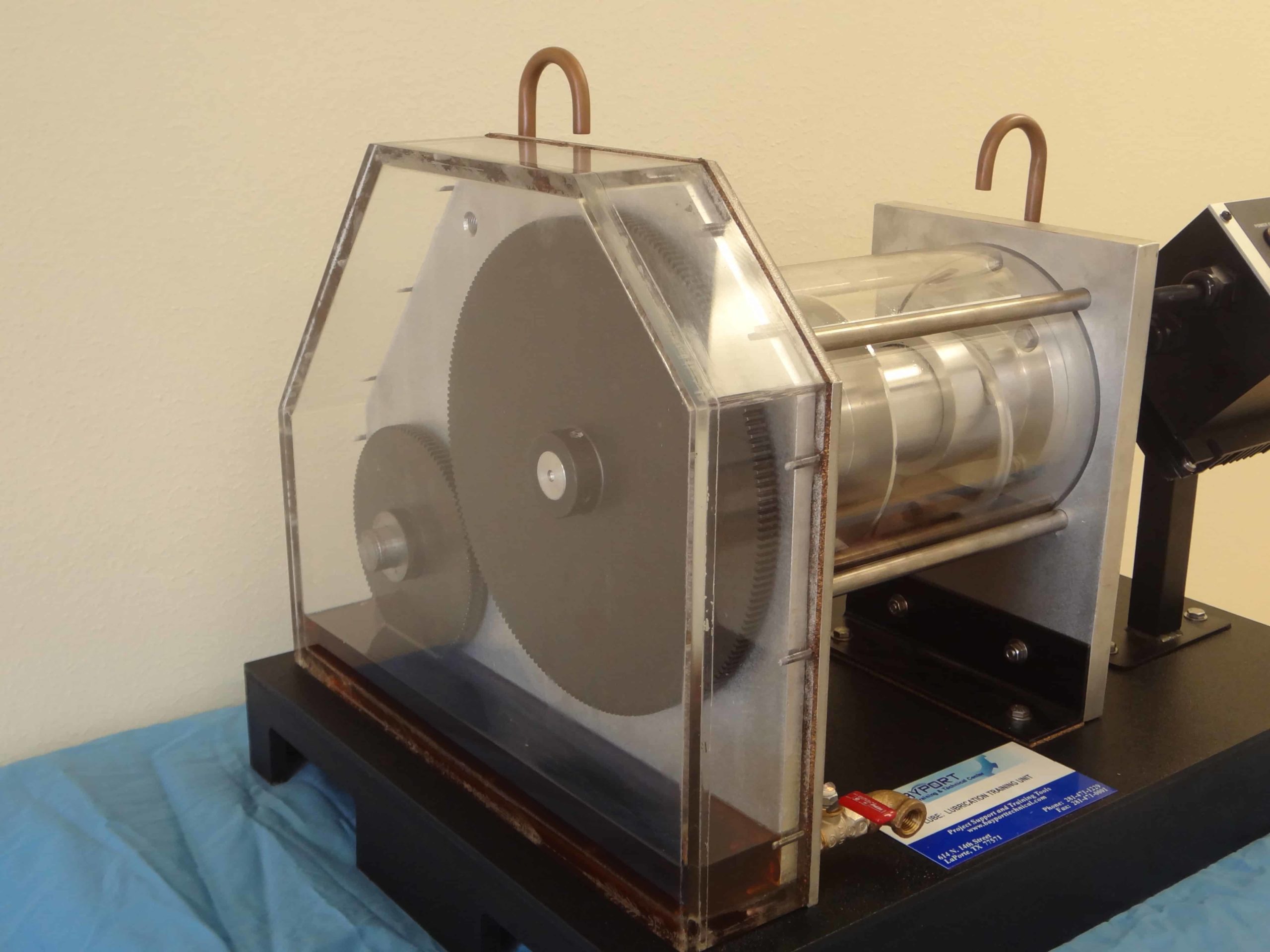

152-LUBE | Lubrication Working Demonstrator

Bayport Technical's Lubrication Working Demonstrator - Acrylic (152-LUBE) is an acrylic model showing three of the most common methods of using a static pool (reservoir) to lubricate bearings.

The unit is equipped with a variable speed motor, which allows the shaft to run slowly and at operating speeds. This allows students to observe the lubrication process as well as rotating equipment such as the shaft and coupling.

This centrifugal pump lubrication system enables you to see how the lube system works. The model visibly shows a slinger ring and bushing with a bushing ring picking up oil and applying it to the pump bearing and bushing. Bearing, slinger, shaft, and bushing are all visible to aid in identification and training. This model also visibly shows gear lubrication in an aluminum and clear acrylic housing. The pinion gear, driven by a DC motor, meshes with a bull gear. The pinion gear runs in oil and carries oil to the larger bull gear. All this is visible via a clear acrylic cover.

The drive motor is a 90 VDC permanent magnet direct current motor with a remote mounted rectifier controller. This controller will regulate speed control within 5% of nameplate RPM and provides full-wave rectification. This drive will provide 0.5 HP at 1725 RPM which is the rated nameplate RPM. Reduced HP is provided at less than nameplate RPM. A stop, clockwise or counter-clockwise 3-way toggle switch controls the shaft rotation. Either rotation will demonstrate the lubrication system. After the desired rotation is selected, a 0-100% speed knob is adjusted between 25-50% for normal lubrication demonstration. Full range adjustment can be made without damaging the unit. Both oil reservoirs have vents located at the top of each reservoir. The vents will prevent the reservoirs from being pressurized. In addition, this is the point where oil is added.