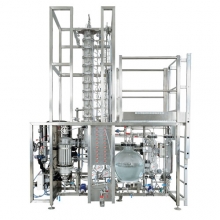

Controlled Absorption & Regeneration Unit

Pignat's state-of-the-art, hands-on Controlled Absorption & Regeneration Unit (ABR/3000) allows students to study the gas-liquid absorption process and the regeneration solvent process all-in-one. The solute migration process from the gas to liquid phase occurs when both phases are in contact in the packing of the reverse flow absorption column. This highlights the absorption operation (solvent purification).

The regeneration process is observed on the second column, which is continuously fed. An energy‐saving heat exchanger is placed between the two columns to optimize energy usage. With this unit, students are able to study various control loops, determine mass balance, and process efficiency. The unit also includes a LabView monitoring system.

Features

- CO2 capture technology implementation

- Unit delivered with educational handbook and technical documentation

- Possibility to customize the unit

- Commissioning & training on site

Instrumentation

- 12 temperature probes Pt100Ω

- Level detector (pressure transmitter)

- 2 manometers

- 2 CO2 analysers

- Differential pressure transmitter

Specifications

- Absorption column, glass Raschig rings packing

- Liquid distributor

- 2 gear pumps

- SS exchanger, energy recovery

- SS preheating exchanger

- SS cooling exchanger

- Regeneration column, glass Raschig rings packing

- 6L glass boiler with inside SS coil

- Condenser, glass shell, SS coil

- Reflux line

- Gas mixture feeding circuit with control mass flowmeters

- Steam line with control valve

- 2 CO2 transmitter—analysers