Smart Robot Logistics Palletizing Workcell

Manufacturers are increasingly turning to smart technology to automate more of their processes by using smart robots to de-palletize and palletize. However, these robots still need human operators to function properly, and many manufacturers struggle to find qualified individuals to operate and maintain these complex machines. Amatrol’s Smart Robot Logistics Palletizing Workcell remedies this by equipping students with the necessary skills they need and pursue successful careers in advanced manufacturing.

The 87-SWPF1V Smart Robot Logistics Palletizing Workcell teaches students how to operate, program, maintain, and troubleshoot a robotic palletizing workcell. Students will learn how to power-up and jog an industrial robot workcell using an HMI, operate the workcell both manually and automatically, enter and interpret commands, configure robot vision settings, track robot performance, and ensure safety devices are functioning correctly.

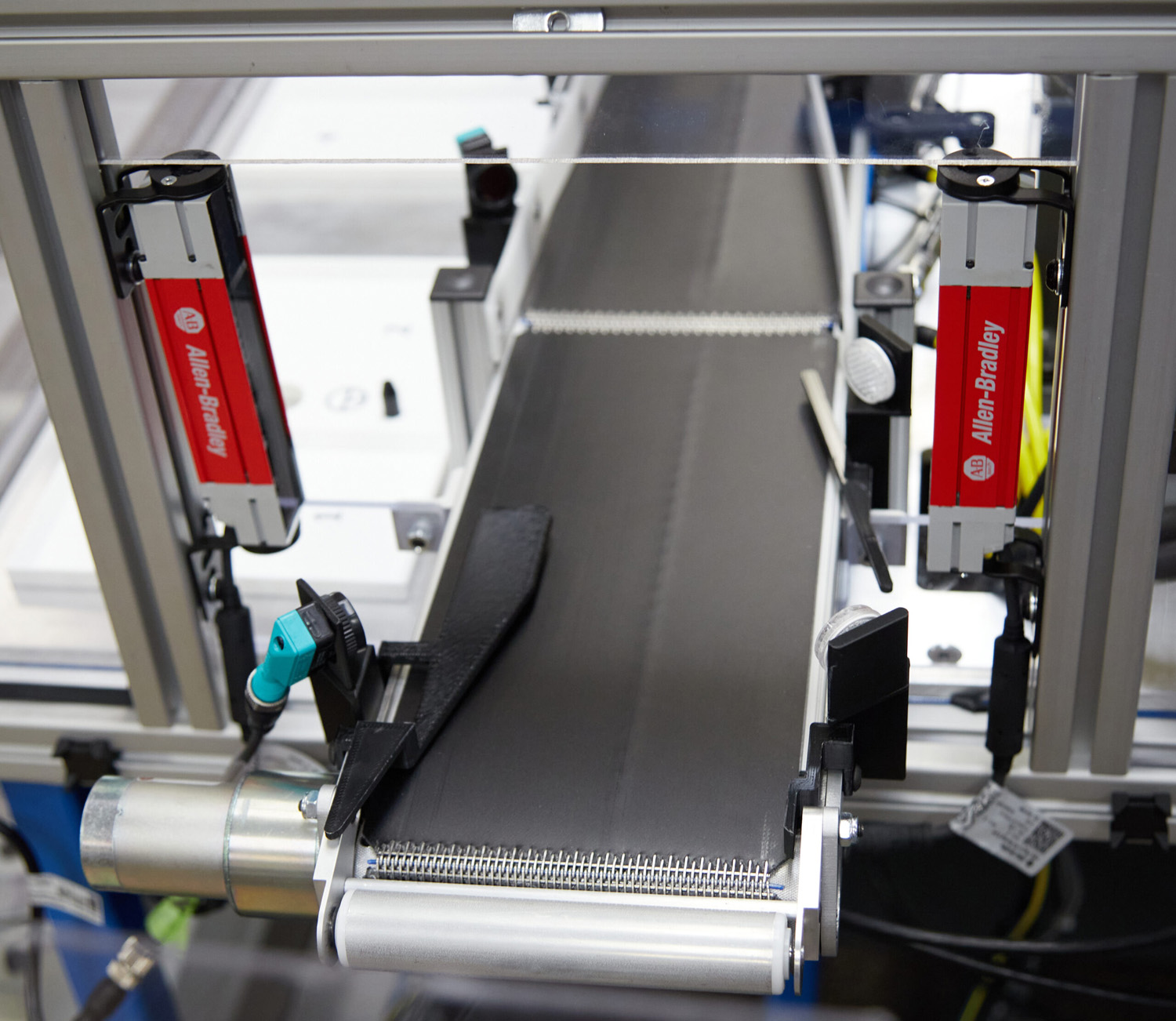

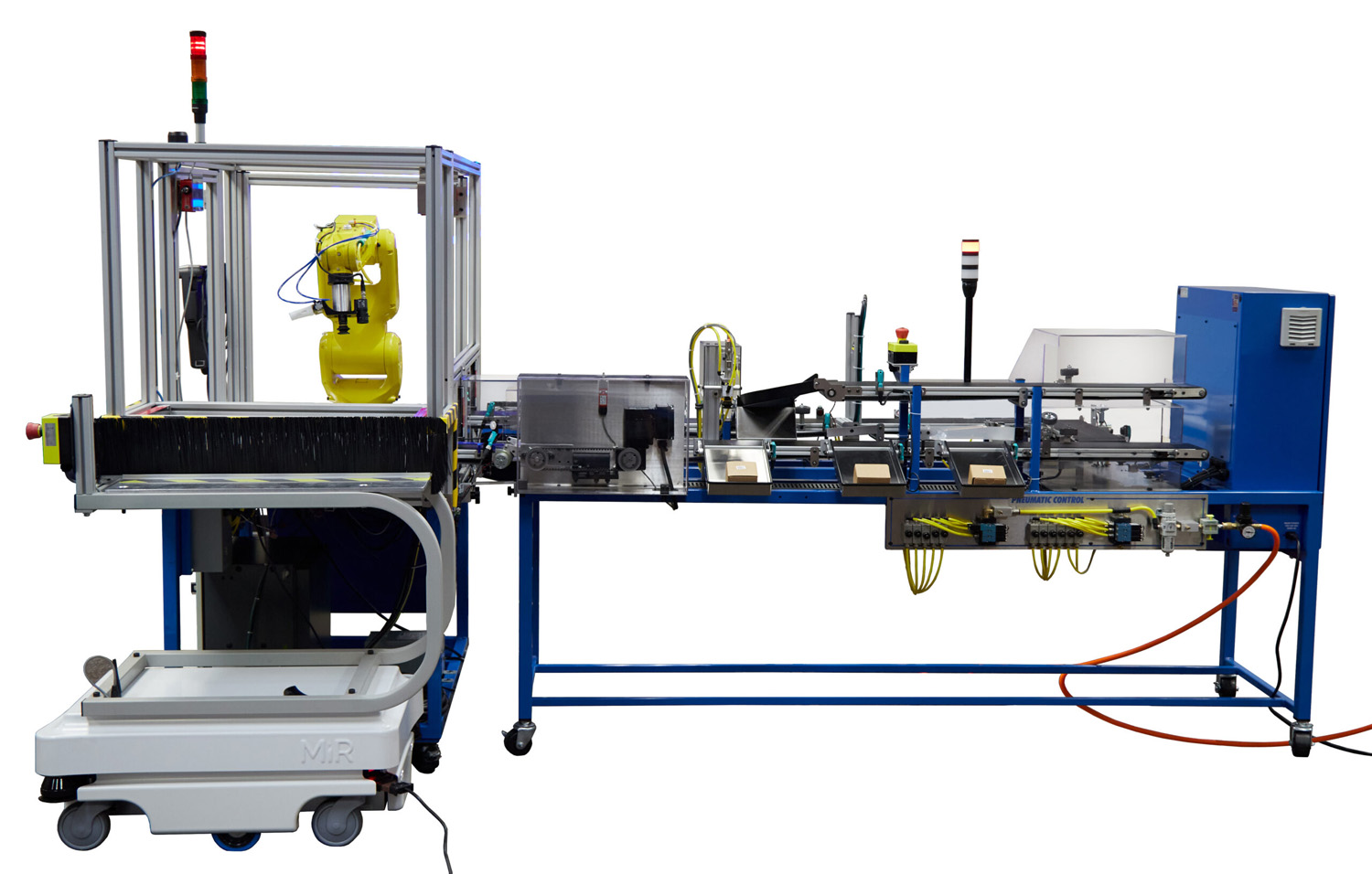

The 87-SWPF1V includes a mobile workstation with a FANUC 6-axis robotic arm, Allen-Bradley safety PLC, dual transport conveyors, and physical safety guards. Five 3D-printed pallets, twenty boxes, and barcode labels are included for sorting. Amatrol’s proven PC-based interactive, multimedia student curriculum is included, as well as an install guide, instructor’s guide, and skills PDF.

87-SWPF1V shown with 87-MRL1 Mobile Robot Logistics System and 95-MSB3 Skill Boss Logistics

Teach Skills Hands-On

Hands-On Operation, Safety, and Troubleshooting Practice

The 87-SWPF1V provides all the components students need to practice real-world hands-on skills that are necessary to operate a robotic palletizer workcell. Using the robotic arm and its vision guidance capabilities, students will test and adjust joint travel limits, configure robot vision settings to capture and identify an image, and design a program to sort packages by reading barcodes. The variable speed electro-pneumatic transport conveyors are equipped with multiple safety devices, such as light curtains with photo eye sensors and a stack light, that students will test to recognize proper safety practices.

The PC-based HMI software that accompanies the system teaches students to navigate multiple control menus, such as 2D/3D workcell overview, subsystems, system schematics, an alarm screen, and order entry. Utilizing these menus, students can operate the workcell manually, create sample customer orders, acknowledge system alarms, and more. The system also includes FaultPro, Amatrol’s computer-based fault-insertion system, that allows students to troubleshoot faults in multiple areas of the workcell.

Optional Mobile Expansion

The 87-MRL1 Mobile Robot Logistics System is an optional add-on to this system. The autonomous mobile robot (AMR) can dock on one side of the robot cell, and the robotic arm’s programming can be adjusted to load and unload pallets from this new location. The AMR can then be used to transport boxes and pallets between two 87-SWPF1V workcells in the same room, enabling students to build more complex programs.

Comprehensive Multimedia Curriculum

Amatrol’s unmatched, highly-interactive multimedia uses text, voiceover, 3D graphics and diagrams, and animations to appeal to multiple learning styles. The 87-SWPF1V’s curriculum covers a range of topics, which guides students from the basics of identifying a robot workcell’s components to entering and interpreting a variety of commands. By course completion, students will have successfully developed and tested their own basic programs to palletize, de-palletize, and pick and place boxes and pallets.

Additional Information

Learning Topics

- Robot Startup and Jogging

- Manual and Automatic Robot Operation

- Palletizing Robot Workcell Operation

- Robot Programming

- Operate and Test a Safety PLC

- Managed Ethernet Switch Operation

- Network Security and Performance

- Basic Industrial Ethernet Operation

- Basic Ethernet/IP Operation

- Robot Vision System Programming

Requirements

- Skill Boss Logistics (95-MSB3)

- 82-750 Factory Talk View ME Station Software

- 82-8RSL Studio 5000 Lite

- 33883 Integration Kit

- 90-START4.4 Engineering Services and Start-Up

- Knowledge of basic FANUC programming

- Computer: See requirements

Utilities:

- Electric (115 VAC/60Hz/1 phase)

- Compressed air

Options:

- 87-MRL1 Mobile Robot Logistics System