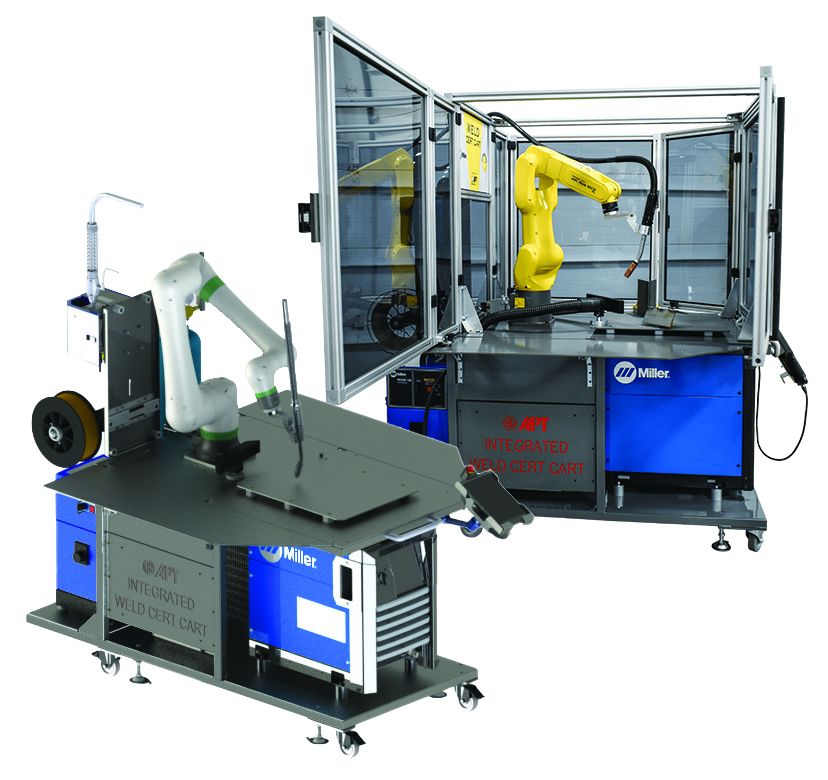

Weld CERT Cart

Welding programs that want to teach the latest technologies will add robotic welding – the future of welding — to their program offering.

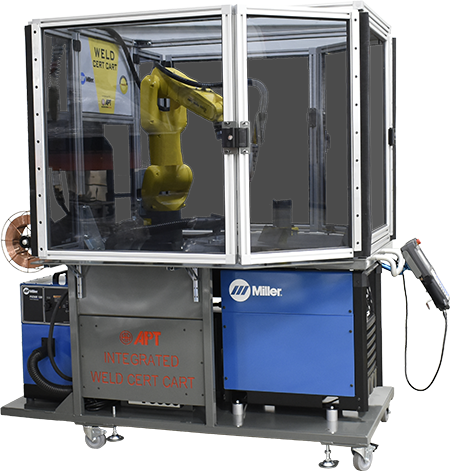

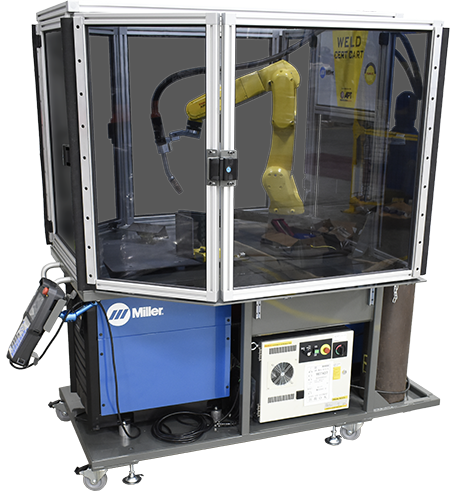

Integrated by APT Manufacturing, this weld cell uses a FANUC ARC Mate 50iD/7L arm with a Miller power source. FANUC’s ArcTool software will make learning robotic welding programming simple. It even uses the same R30iB Mate controller used on FANUC’s educational robots.

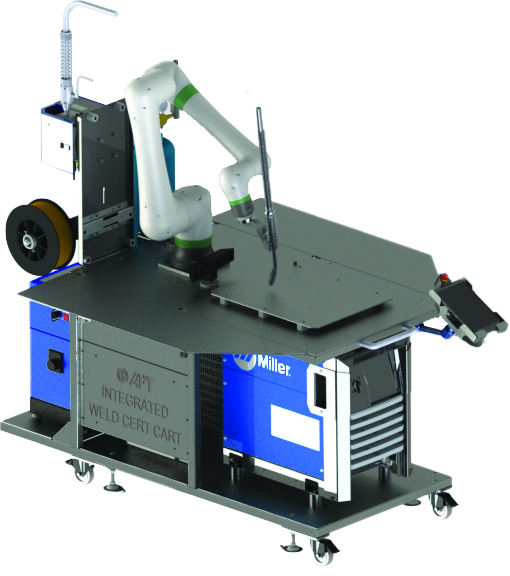

Options

- ArcMate Cart

- CRX Cart

Certified Robotic Welding Trainer

- Qualifies for FANUC educational CERT program

- Integrated system with FANUC equipment

- Integrated system with Miller equipment

- Ships with project-based learning

- Fits through standard 36" door

Certifications, Curriculum, & Software

FANUC ARC CERT

- FANUC ARC CERT Gift in Kind Package for qualified schools.

- FANUC Advanced Academic Software/ARC Bundle

- FANUC ARCTool Student Certificate Program

- Optional iRVision

OpenBook™

OpenBook™ is Miller’s learning management software. It’s designed to help you plan, offer, and assess student learning. It provides welding instructors, learners, and management with an easy tool to teach welding concepts and techniques to a variety of students from those just starting out to professionals in the field who’d like to learn new skills or refresh their current techniques.

Integration Project-Based Learning (PBL) Curriculum:

- Daily lesson plans

- Assessment and grade charts

Features

- Welded Construction

- Tinted sides to protect classroom (helmet required for viewing)

- Fully Integrated collapsible mobile cart design, fits through standard 36″ door

- Robot work area guarded for student safety

- Dimensions: 80″ L x 63″ W x 78″ H

- Collapsed dimensions: 80″ L x 33″ W x 78″ H

- FANUC ARC Mate 50iD/7L: high-speed ARC welding robot

- FANUC R30iB Mate plus controller

- Standard IP67 rating gives it the versatility to work in harsh environments including dusty and wet areas

- 6 axes

- Up to 7kg

- Precise arc welds

The FANUC ARC Mate 50iD/7L is a high-speed ARC welding robot that is equipped with added reach. Its standard IP67 rating gives it the versatility to work in a variety of different harsh manufacturing environments including dusty and wet areas. With 6 axes, this robot can carry up to 7kg while creating precise arc welds.

With FANUC’s ArcTool software, learning on the ARC Mate 50iD/7L will provide students with the knowledge and confidence to operate a variety of FANUC ARC Mate Series Robots and support employer’s need to develop more efficient and profitable welding processes.

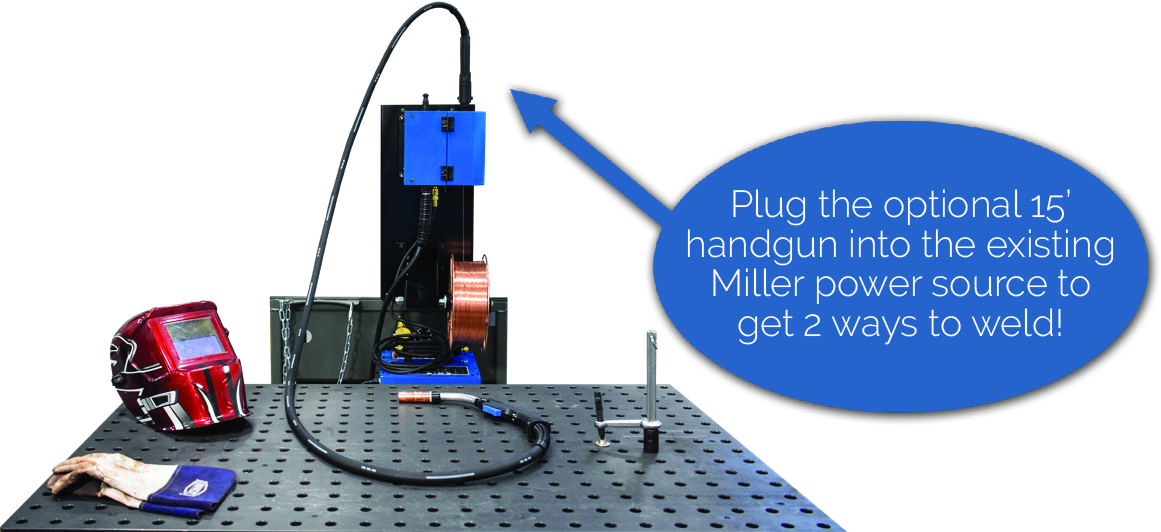

Auto-Continuum™ Systems

Easily add new processes and custom programs via the USB interface.

Parameter flexibility allows the systems to be set for voltage and wire feed speed control, or for voltage and amperage control.

Versa-Pulse™:

- Fast, low-heat, low-spatter process – for high-speed automation on materials 1/4 inch (6.35 mm) and thinner.

- Great for gab filling

- Shortest arc length/lowest pulse voltage for lower head and lower spatter at higher speeds

Accu-Pulse®:

- The most popular process for the majority of industrial welding applications

- Most adaptive arc on 16 gauge (1.6 mm) and thicker

- Designed for all weld positions

RMD®:

- Lowest heat process, best for gap handling

- Limited travel speed