Hands-On Allen-Bradley ControlLogix Skills

Amatrol’s PLC EtherNet Training System (89-EN-AB5500) teaches the fundamentals and troubleshooting of industrial communications networks using EtherNet/IP. EtherNet/IP has become very popular as an industrial communications network, offering high data transfer speed, flexibility of communicating on both the Enterprise level and the Automation and Control level, and a choice of vendors when purchasing equipment. It is important for technicians to understand different types of networks and their operation to be able to install and troubleshoot not only networks, but also the interconnections to the PLCs.

The main components of the 89-EN-AB5500 are two EtherNet/IP PLC modules and two EtherNet 5-port switches. Learners will use these components with additional required learning systems including the PLC Troubleshooting Learning System – AB ControlLogix (890-AB5500) to practice fundamentals such as: basic PLC operation and programming, motor control, event sequencing, I/O interfacing and testing, process control, and material transfer. Amatrol uses industrial-quality components for durability to stand up to frequent use and so that learners can get real-world experience with components that they’ll actually see in the field.

Add-On Options for 890-PECB

The PLC Expansion Package (89-MP) Expansion Module adds to the 890-PEC-B Troubleshooting Learning System to create dual PLC training system. The 89-MP is an ideal method of teaching applications such as remote I/O and Date Highway Networks, where multiple PLCs are required. With just one learning station, learners can set up a multiple PLC network between the PLCs mounted on the 89-MP and the 890-PEC-B.

The 89-MP is also a cost effective way to support multi-brand or model training. Two different PLCs can be mounted on the learning station at all time so changeover between the two PLCs only requires the student to connect a new quick-connect cable set.

The Electrical Relay Control Training System (90-EC1A) teaches how to interpret, design and operate relay control circuits using ladder diagrams. Electrical control is vital in the operation of electric and fluid power actuators and also forms the fundamental building block of automation systems like programmable logic controllers (PLCs), which are programmed using the electrical control schematic method, the ladder diagram.

The Electrical Relay Control Training System includes a tabletop console with pre-mounted electrical control, pneumatic, and electri power components. Each component's electrical terminals are connected to heavy-duty banana jacks, enabling learners to quickly connect and operate various automation control circuits.

The training system also features in-depth curriculum covering major topics including control logic, ladder diagrams, sequencing control, timers and advanced systems.

Amatrol’s Design of Structures 1 Learning System (94-DOS1) serves as an introduction to civil engineering and covers the design, construction, and analysis of structural designs, such as bridges, buildings, and tunnels. Design of structures introduces learners to the various roles that civil engineers can assume in the residential, transportation, and industrial fields. This system features world-class curriculum that intertwines theoretical lessons such as how to calculate the bending stress in beams with practical skills like building and testing a Warren Truss bridge.

The design of structures training system includes two bridge component sets that can be used to construct a variety of truss bridges, a beam component set to show how different loads affect beam stress, and a data acquisition system to test the stress on various components. These components will help learners to build skills that can be applied in the workplace, which is one example of how Amatrol transforms the global workforce one life at a time.

Concrete Beam Construction & Testing Training System

Amatrol’s Design of Structures 2 Learning System (94-DOS2) expands on 94-DOS1 concepts and covers topics like beam deflection, column buckling, concrete, building design, and construction. The 94-DOS2 introduces learners to theoretical principles such as how different types of loads affect a structure and then allows them build a scale model of a four story building frame and test how different stresses act on it. This marriage of theory and hands-on skills reinforce important structural design concepts and show learners how they apply to houses, office buildings, cathedrals, malls, and more.

Among many other components, the 94-DOS2 includes a concrete beam component set that allows learners to mix and set their own concrete beams, then test them for weaknesses. Providing components that allow learners to build and test structural elements while working through the world-class curriculum is one reason that Amatrol is the world’s leader in skills-based, interactive technical learning.

Amatrol's Design of Structures 3 (94-DOS3) covers the basic principles of surveying, surveying equipment, reading and interpreting maps, and global positioning systems. Surveying involves taking measurements of land and its features and then processing this information into usable data. Surveying provides essential information used by construction professionals, civil engineers and more!

The Design of Structures 3 Training System includes a level-transit kit, global positioning system, interactive multimedia surveying curriculum, an instructor's guide, an installation guide and a student reference guide. This equipment and curriculum will be utilitzed to cover vital topics like level-transit operation, trigonometric survey application, topographical maps, global positioning system applications, and more!

Robotics and Computer Programming

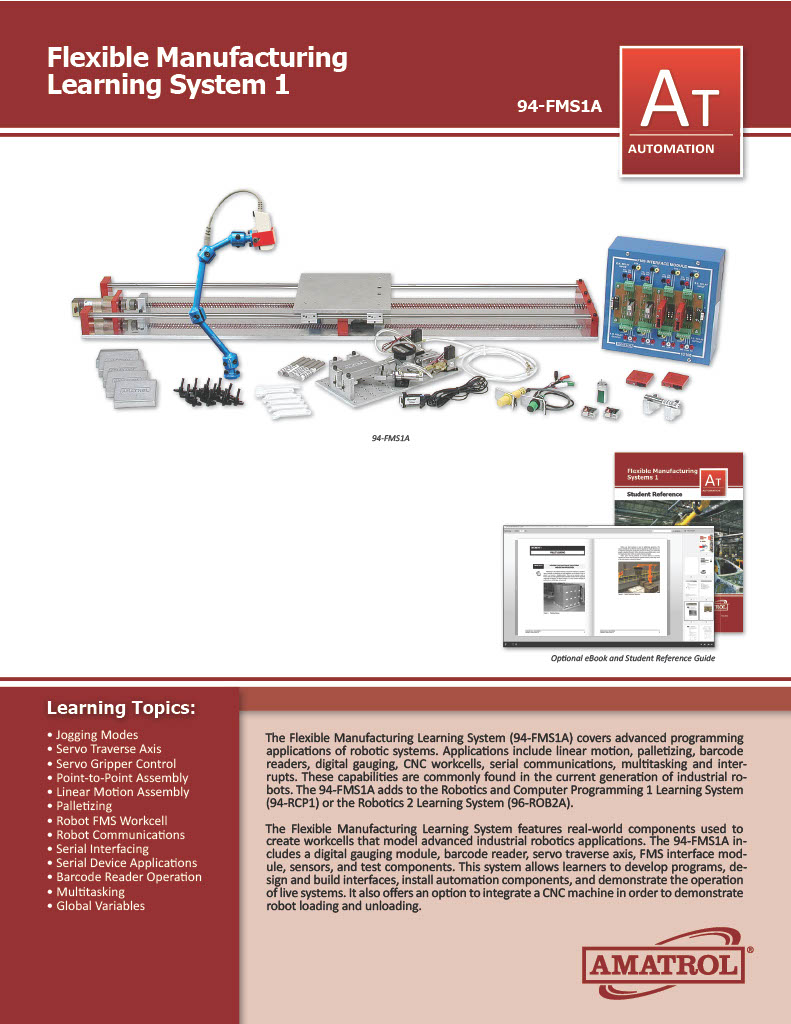

The Flexible Manufacturing Learning System 1 (94-FMS1A) adds to either the Robotics and Computer Programming 1 Learning System (94-RCP1) or the Robotics 2 Learning System (96-ROB2A) to teach advanced programming applications of robotic systems. Applications include linear motion, palletizing, barcode readers, digital gauging, CNC workcells, serial communications, multitasking, and interrupts. These capabilities are commonly found in the current generation of industrial robots.

The model 94-FMS1A provides real-world components students will use to create workcells that model industrial applications of advanced robotics. Students will develop flexible manufacturing robot programs, design and build interfaces, install automation components, and demonstrate the operation of live systems. Amatrol’s Flexible Manufacturing Learning System includes a digital gauging module, barcode reader module, servo traverse axis, FMS interface module, sensors, test components, student learning materials for theory and lab, and teacher’s assessment guide. The learning materials also support the use of an optional CNC machine module to demonstrate robot loading and unloading.

Injection, Blow, & Extrusion Molding Skills

Amatrol’s Plastics Technology Learning System (94-MP3T) is an all-in-one trainer that can perform injection molding, blow molding, and extrusion molding! With the ability to hold four ounces of plastics, the plastic injection molding training unit can perform multiple molding shots without learners needing to refill the system and wait for the plastic to melt. Additionally, this system features two digitally-controlled heater jackets located on the system’s barrel and nozzle to create dual temperature zones, which is a standard feature on industrial plastics machines.

Plastics are used in nearly every industrial area from automotive to food and beverage. Besides strong hand-on learning, the 94-MP3T features thorough theoretical knowledge that not only intricately explains the processes, operation, safety, and troubleshooting of the three major types of molding, but also offers curriculum in basic chemistry and then provides an in-depth look at polymers and the properties of plastics. The curriculum also covers safety data sheets (SDS) and plastics system purging.

Hands-On Testing & Polariscope Skills

Material strength properties affect the performance and safety of almost every product made. As technology has advanced, material choices have broadened and become more complex. Engineers and technicians alike must be able to select the proper material for an application and analyze material properties when a product fails. That calls for industrial materials testing.

Amatrol’s Materials Engineering 1 Learning System (94-MT1) uses industrial quality components to teach students how to evaluate and use different industry grade materials. The 94-MT1 allows students to conduct a wide array of tests including tensile testing on steel alloys. Students learn industry-relevant skills in materials testing (tensile, compression, hardness, and shear), computerized data acquisition, chemistry of metals, interpretation of industry-standard numeric identification systems of various types of metals (steel, aluminum, brass, and copper), material strength analysis, and product design.

Hose and Tube Fitting

Amatrol’s Pneumatic Fitting Construction Learning System (94-PFC-1) covers how to select the proper fittings required for connecting components and installing fittings to hoses and flexible tubing. Major topics covered by the Pneumatic Fittings training system include air supply connections, control air connections, and power air connections. The topics and pneumatic skills included in this system are required knowledge for any technician or engineer involved in the construction of pneumatic systems.

The Pneumatic Fittings training system includes a tabletop workstation with pre-mounted pneumatic components like a pneumatic cylinder, flow control valve, manifold, and directional control valve. Learners will use these and other components to practice skills like installing a rubber hose onto a push-on type fitting, connecting tubing using a ferrule type fitting, and installing a bulkhead fitting. Working with these industrial-grade components will help learners gain confidence and build real-world applicable skills for rewarding careers like industrial maintenance technicians.

Pages

-

Meet high production demands with the Stratasys H350 powder bed fusion 3D printer. Leveraging Selective Absorption Fusion, SAF technology, into the H-Series production platform, the Stratasys H350 is designed to deliver functional, production-grade parts with unrivaled consistency.

-

Item Number:J4100Whatever the complexity, the J4100 can handle any design. An ultra-large build tray, multi-material capabilities, fast throughput, and a wide range of material properties mean unlimited design possibilities and improved productivity.

-

Item Number:J850 Pro / J850 Prime / J826 PrimeFrom ideation to creation, the J8 Series delivers a fully-functioning, multi-material, Pantone™ validated prototype 200% faster than traditional methods.

-

The J850™ TechStyle™ 3D printer is powered by 3DFashion™ technology and provides full-color, multi-material capabilities for designs that can be printed directly to fabric, garments, footwear, and luxury accessories, delivering results that are not possible with traditional methods.

-

Item Number:Neo450e / Neo450sThe Stratasys Neo450e is an affordable industrial-grade 3D printer producing small to medium parts with consistent accuracy and repeatability. The Neo450s offers performance and versatility along with all the benefits of Neo450e.

-

Item Number:NEO800The open-system Stratasys Neo800 3D Printer uses Stereolithography (SL) technology to delivers high-quality parts with superior surface quality, accuracy, and detail at unprecedented speeds.

-

Objet30 Prime offers four additional materials expanding to rubber-like materials for soft-touch features, flexible components, and even bio-compatible for medical device prototyping and end-use parts such as surgical guides.

-

Item Number:275-125DAC Worldwide’s Submersible Vertical Turbine Pump Dissectible (275-125) is an actual industrial pump for use in classroom and laboratory training relating to process pumps.

-

Item Number:275-120DAC Worldwide’s Submersible Vertical Turbine Pump Dissectible (Goulds/IR/Durco/Aurora) (275-120) is an actual industrial pump for use in classroom and laboratory training relating to process pumps.