Stratasys 3D Printers

Trusted Leader in Innovative 3D printing and Manufacturing Solutions

Tech-Labs finished in the "Top 30 Stratasys Reseller in the World," and have been recognized by Stratasys as a Platinum Reseller!!! This is extremely difficult to achieve and we are proud to be the only Educational Reseller to receive this honor in our territory.

Stratasys, is a leading provider of high-quality, cost-effective Fused Deposition Modeling (FDM) & inkjet-based 3D printing systems and materials. A global company, Stratasys has offices in North America, Europe, Japan, China, Hong Kong, and India.

Stratasys FDM & PolyJet’s solutions can be typically found in industries ranging from to aerospace to medical, architecture, industrial machinery, footwear, sporting goods, toys. Stratasys 3D printing systems and 3D printing materials are ideal to allow students to design physical models using 3D software or other 3D content. Stratasys 3D printers can also be found in many K-20 educational institutions and research centers worldwide.

Visit Stratasys' Website to learn more!

-

Item Number:F170 / F370The Stratasys F Series is the ultimate, all-in-one rapid prototyping system for your entire team. It combines the power of FDM with the ease of GrabCAD Print for the most versatile and intelligent solution available.

-

Item Number:J55The Stratasys J55 Prime 3D printer introduces full color, high fidelity with tactile, functional, and sensory capabilities - making the efficiency and quality of PolyJet Technology more affordable and office-friendly than ever.

-

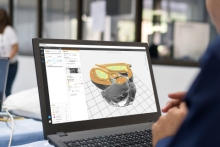

Item Number:J850 DAPThe Stratasys J850™ Digital Anatomy™ 3D Printer combines materials and software to create 3D medical models of human anatomy that mimic bone and tissue with realism you can see and feel.

-

The Digital Anatomy Creator (DAC) is a powerful tool that creates unique presets, prepares models for printing, and enables sharing projects.

-

Item Number:F190CR and F370CRIt starts with high-strength composite materials, but the Stratasys composite-ready F Series offers much more. More materials, more reliability – more capability than other similar printers.

-

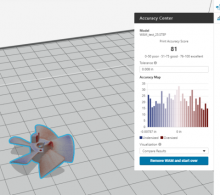

The premium version of GrabCAD Print™, GrabCAD Print Pro™, supports high-performance end-use parts or prototypes utilized in process-controlled conditions. This includes enhanced features such as Accuracy Center, Manufacturing Templates, 3rd Party Plugins, and Per-Part Estimation. Additional features will be included in future releases.

-

The Stratasys J35™ Pro is an affordable, versatile PolyJet 3D printer suitable for shared spaces offering multi-material capabilities.

-

The Stratasys MediJet™ is setting a new standard for medical printing. With multiple materials and multicolor capabilities, you can create brilliantly vivid anatomical models and drilling and cutting guides* that are sterilizable and biocompatible - all on a certified system.

-

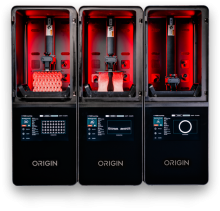

A transformative 3D printer enabling mass production of end-use parts in a diverse range of high-performance materials. Achieve industry-leading accuracy, consistency, detail and throughput with the P3™ Programmable Photopolymerization technology.

-

Elevate Your 3D Printing Game with Stratasys' F3300 FDM 3D Printer: Experience Cost Savings, Increased Throughput, Superior Quality, and User-Friendly Operation – Unleash Innovation Today!